NOVA™ LNP Production:

GMP Manufacturing

Step into the future of lipid nanoparticle (LNP) production with Helix Biotech's Nova™ Impinged Jet Mixing (IJM) system, designed to streamline your path to GMP-compliant manufacturing.

Whether you're scaling up to clinical or commercial volumes or fine-tuning formulations, the Nova™ IJM delivers the precision and consistency you need to produce high-quality LNPs effortlessly.

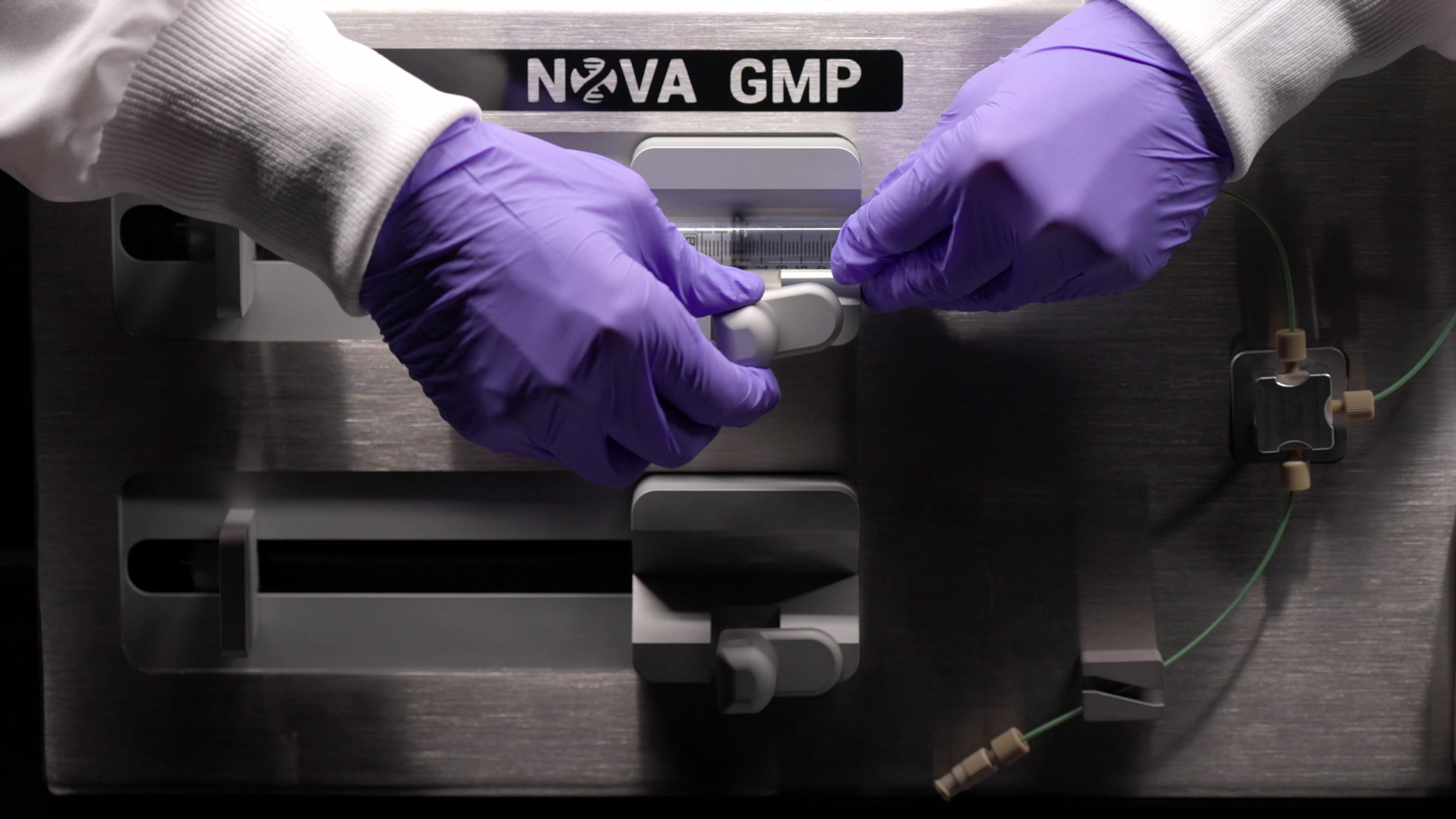

Nova™ Benchtop GMP

Helix Biotech Nova™ BT GMP

System Features

GMP-Compliant LNP Manufacturing

21 CFR Part 11 Compliant Software

Nova™ provides full 21 CFR Part 11 compliant software. The system includes audit trails, electronic signatures, and secure data storage to maintain the highest level of traceability and security.

Flexible Scalability

Designed for both R&D and full-scale production, Nova™ offers scalable solutions that can easily transition from small-batch development to large-scale GMP manufacturing. This flexibility allows companies to streamline their process development and scale-up phases, ensuring that the same high standards are maintained throughout.

Automated Process Control and Monitoring

The Nova™ can feature automated process control that provides precise monitoring and adjustment of critical process parameters in real time. This system can provide real-time pressure or flow rate sensors to ensure consistent production of GMP-grade material.

Advanced Tech

We are constantly working to improve our offerings and expand upon our technological capabilities. Our expert team of professionals is passionate about developing the most advanced instruments on the market. Ready to experience innovation? Get in touch.

Turbulent Mixing for GMP LNP Manufacturing

Turbulent Mixers Produced Billions of COVID-19 Vaccine Doses

The global response to the COVID-19 pandemic highlighted the importance of scalable and efficient LNP manufacturing. The large-scale production of these vaccines was made possible by leveraging turbulent mixing technologies. The success of these vaccines has not only demonstrated the effectiveness of turbulent mixing in large-scale LNP production but has also set a new standard for future vaccine and therapeutic development.

Understanding Turbulent Mixing in GMP LNP Manufacturing

Turbulent mixing involves the chaotic and rapid interaction of fluids, which enhances the efficiency and speed of mixing. In the context of LNP manufacturing, turbulent mixing is achieved through specialized mixers such as impinging jet mixers (IJMs) and multi-inlet vortex mixers (MIVMs). These devices create a turbulent flow by forcing streams of lipid and aqueous solutions to collide, leading to the rapid formation of uniformly sized nanoparticles.

This method offers several advantages over traditional laminar flow techniques (e.g. Microfluidics), particularly in terms of scalability and production speed. The intense mixing conditions ensure that the lipid and RNA components are combined quickly and efficiently, resulting in a more homogeneous and consistent product. Moreover, turbulent mixing allows for larger batch sizes, making it an ideal choice for scaling up production to meet commercial demands.

IJM

Uniform Lipid Nanoparticles

Figure 1. Nucleic acid in an aqueous phase and lipids in ethanol are introduced by forcing the two streams into an impinged jet mixer to induce homogeneous and rapid mixing, producing uniform lipid nanoparticles.

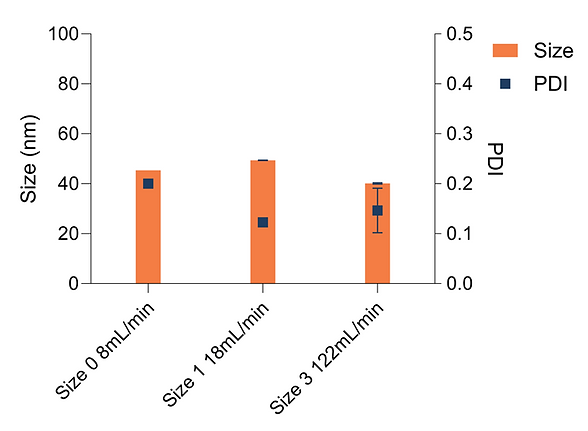

NOVA™ Bridges R&D Scale and Clinical/Commercial Manufacturing

One of the key advantages of the Nova™ platform is its ability to maintain consistent mixing conditions across different production scales. The turbulent mixing process ensures that the critical quality attributes of lipid nanoparticles (LNPs), such as particle size, polydispersity index (PDI), and encapsulation efficiency, are preserved from the R&D phase through to large-scale manufacturing.